Advantages

SmartVide Track: advantages

1. Unique working system

SmartVide Track is a global innovation, as it's the only sous-vide system which offers timing for individual portions. It has been developed in conjunction with Fleischmann's Cooking Group to transform vacuum and low temperature cooking into a working system, responding to a real need seen in kitchens

2. Applicable to any type of catering establishment

The solution is applicable to any type of restaurant, whether it's serving haute cuisine, everyday favourites or pub food. Moreover, it is flexible and can be used to control the timings of portions or containers for processes other than sous-vide, as required by users.

3. Highly intuitive to use

The application is very easy to set up and use, and requires very little intervention from the operator who can also carry out other tasks during cooking or regenerating time.

4. Standardisation of processes

By means of time control it is possible to establish standardised processes in the kitchen not only in terms of temperature, but also in terms of regeneration or cooking times.

5. Guaranteed traceability, HACCP control and cooking history

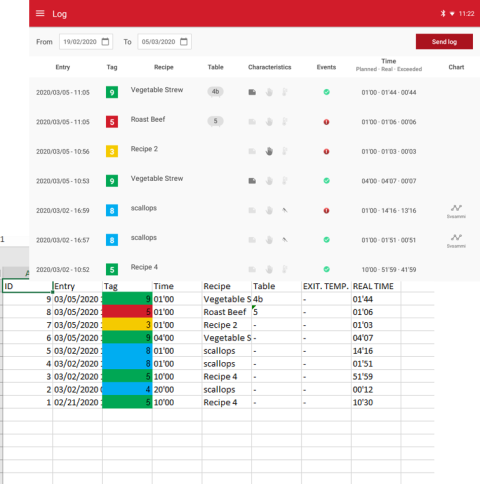

TRACEABILITY: The system keeps historical records of cooking, portion by portion, enabling subsequent monitoring of the cycles carried out. In addition, the individualised control allows special customer needs - such as allergens, salt-free diets, etc. - to be quickly identified and traced. And regeneration and cooking tips from the producer/cook.

HACCP CONTROL: SmartVide Track generates very precise reports of cooking times and temperatures, portion by portion, allowing complete and accurate traceability from the mobile device at all times.

COOKING HISTORY: SmartVide Track allows you to export the historical files so that they can be stored and monitored.

6. Productivity and efficiency in the kitchen

SmartVide Track helps improve kitchen workflows, improving productivity and efficiency. There is no need for an operator to monitor the cycles of the different portions in the sousvide, as SmartVide Track takes care of this monitoring, and operators can concentrate on other tasks during this time.

7. Expansion of the selection offered by the kitchen

Regeneration with SmartVide Track at the time of service makes it possible to closely monitor and offer a greater variety of options in the same service, without affecting service times or the quality of the product served.

8. Highest respect for the product

It allows the quality of the food to be enhanced while respecting the cooking or regenerating times, taking maximum care of the qualities of the produce and seeking the perfect preparation of a given ingredient.

9. Satisfied customers

The expansion of the offer, the guarantee of uniform quality thanks to the standardisation of processes, and the optimisation of service times have a positive effect on customer satisfaction.

10. Improved cost-effectiveness

The efficiency of the workflows and the savings in costs that this entails, together with greater customer satisfaction, have an immediate and ongoing impact on the profitability of the business.

SmartVide Track

Exclusive customised control system for cooking times of individual portions.

SmartVide Track is the only system that allows the cooking times of foods to be traced bag by bag, identifying each container and controlling its cooking time. It provides an exhaustive traceability of the temperature and time historic data compatible with HACCP controls.

SmartVide Track provides maximum productivity and efficiency in the kitchen workflow.

This way, a working system is created that, added to the maximum temperature precision offered by the SmartVide thermocirculator, makes it possible to work with optimum control of cooking times.

SmartVide Track can be used for both cooking at low temperatures and when regenerating.

SmartVide Tags

SmartVide Tools: Supports

SmartVide Tools: Organisation for Tags

Sous-vide cookers

Commercial precision cooker to get the best products.

Temperature-controlled sous-vide cooking has become an indispensable technique for any kitchen that follows the latest trends. This technique allows to obtain more tender, tasty products with the best texture, with the minimum loss of moisture and weight.

- Maximum recipient capacity

| 30 l | Immersion Circulator SmartVide 5 Maximum capacity: 30 l / 8 gal. |

| 56 l | Immersion Circulator SmartVide 7 Maximum capacity: 56 l /14 gal. |

| 56 l | Immersion Circulator SmartVide 9 Maximum capacity: 56 l /14 gal. |

| 120 l | Immersion Circulator SmartVide XL Maximum capacity: 120 l / 30 gal. |

| High production retherming and cooking station The SmartVide XL cooker + 120P heated tank: Serve up to 200 portions of 200 g per hour. |

Any questions?

Enter your enquiry