Turning the problem of steam into an opportunity

Let's take the situation that a hotel has just redesigned its washing area and has launched a new project to ensure the best quality of cleanliness in the hotel. Everything has been designed to be perfectly suited to the establishment and its workflow and the installation goes into operation... But soon the problems begin: the level of humidity in the washing area is very high and the temperatures are through the roof. Because of the heat, workers suffer and, in addition, the installation begins to deteriorate. What is happening?

This can be a common problem in all establishments where the steam generated in washing areas is not well managed. The steam generated in the washing machines increases the humidity level in the washing area causing, among other things, high temperatures in the work area, deterioration of the installation and workers slipping frequently due to wet floors.

How does the steam condenser work?

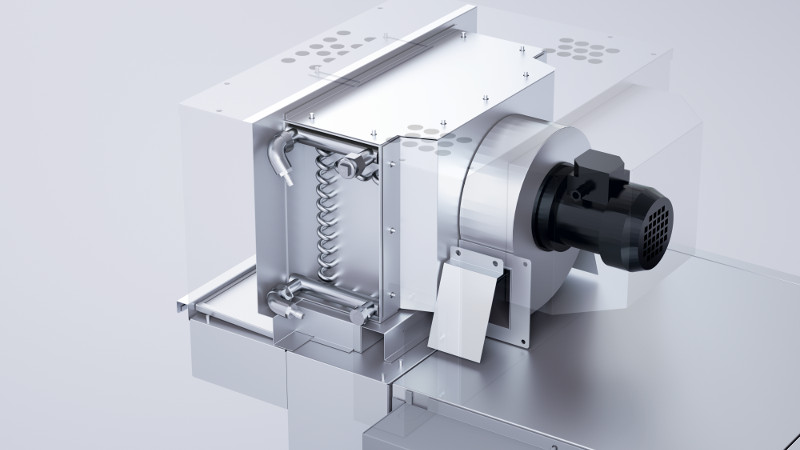

To solve this problem, Sammic proposes steam condensers on all models of its Rack Conveyor Dishwashers SRC and on the Extra and Supra pass-through dishwashers . The Sammic steam condenser absorbs the steam that is generated in the machine and circulates it through a coil. In this coil, a heat exchange occurs between the incoming water, which comes from the network at around 10-20ºC, and the water steam, which has a temperature of about 80ºC. During the exchange, the heat from the steam heats the water that enters the washing tunnel and thereby reuses the heat generated. Thus, thanks to this capacitor, not only are moisture problems avoided and the operator's working environment improved, there is also a large energy saving in the boiler when it comes to heating the water. Specifically, 29% improved the energy efficiency of the machine. However, in addition to energy saving, pre-heating the incoming water also helps the recovery of the boiler's water temperature, improving, if possible, productive capacity and washing efficiency.

What is the payback scenario for the equipment?

Although the steam condenser is optional with an economic cost that is added to the price of the machines, it should be noted that in high-performance washing environments the payback scenario is very reasonable. It is estimated that a site that works 300 days per year and uses the washing machine four hours a day, the condenser will pay back in just four years. To calculate the exact payback time, Sammic has an energy savings calculator that gives custsomized results for each user.

Therefore, the problem of steam is no longer a problem. Thanks to the Sammic Steam Condenser, not only is humidity no longer a problem, the washing area also becomes a more efficient, more productive and more environmentally friendly area.